Product Description:

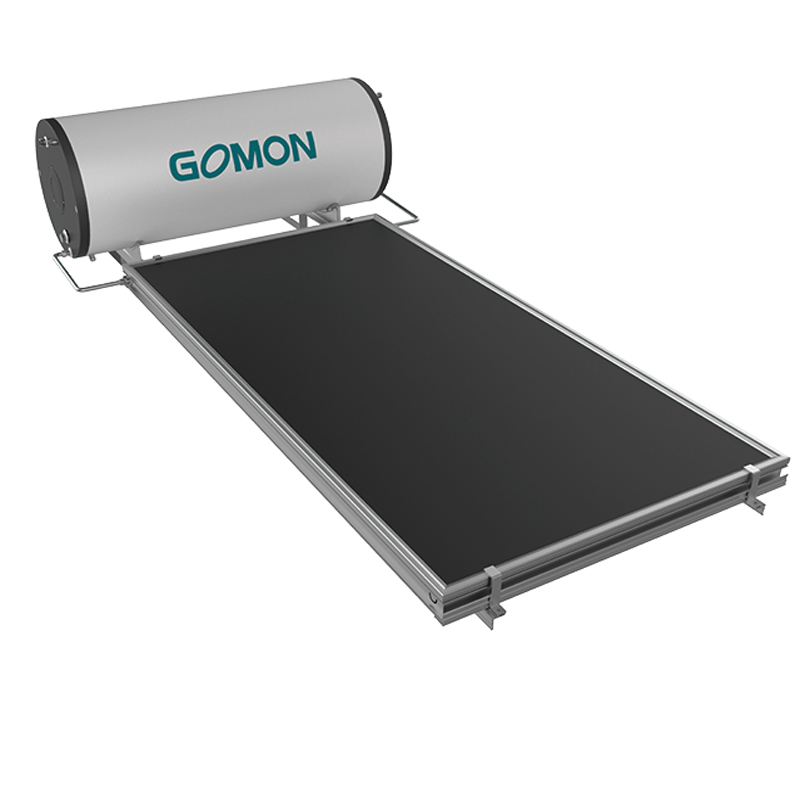

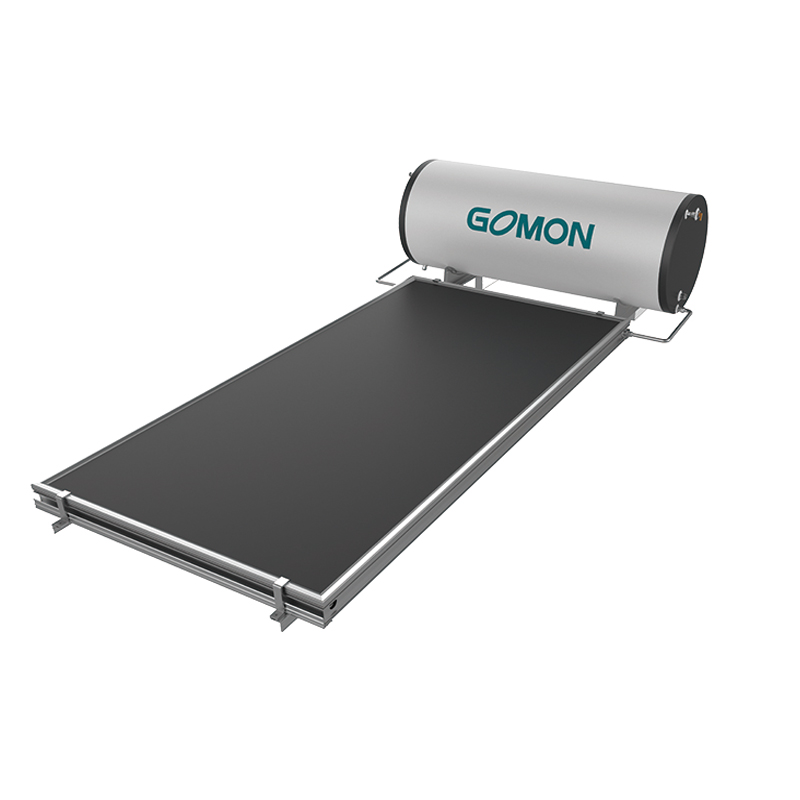

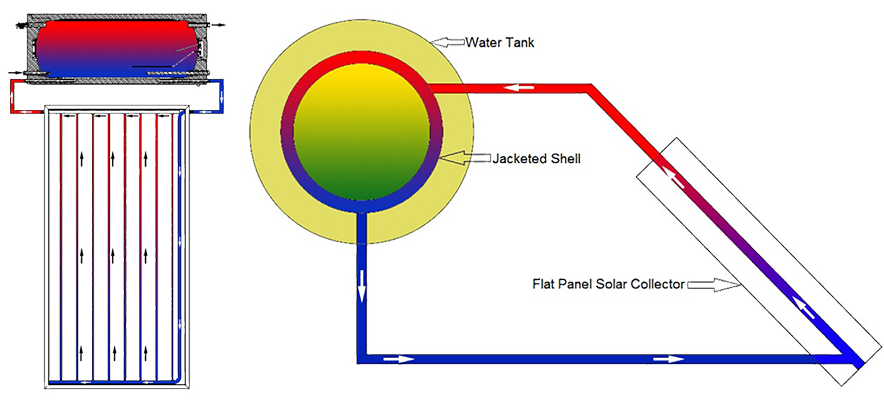

This is a pressurized system, with jacketed tank and flat panel solar collector combined. We call it compact flat panel pressurized solar water heater.

This closed loop system can prevent freezing and scale. Heated glycol-water mixture solution from the collector flows into the tank’s jacketed shell heat-exchanger and then returns to the collector after heating up the domestic water.

Product Features:

The enamel is coated inside the water tank Which is of high corrosion resistance and of Great pressure bearing. Our Porcelain enamel tanks approved by CE, WATERMARK, ETL, WRAS, EN12977-3

The enamel is coated inside the water tank Which is of high corrosion resistance and of Great pressure bearing. Our Porcelain enamel tanks approved by CE, WATERMARK, ETL, WRAS, EN12977-3 The whole system approved by SOLAR KEYMARK (EN 12976 Standard)

The whole system approved by SOLAR KEYMARK (EN 12976 Standard) Imported blue titanium absorber from Germany with high absorptivity(95%) and low heat loss(5%). High purity oxygen-free copper pipes as circulation system with high thermal conductivity, anti-corrosion pressure-bearing and longer service life. Low-iron tempered solar glass as cover with 92% transmittance. Our flat panel solar collector approved by SOLAR KEYMARK(EN12975 Standard)

Imported blue titanium absorber from Germany with high absorptivity(95%) and low heat loss(5%). High purity oxygen-free copper pipes as circulation system with high thermal conductivity, anti-corrosion pressure-bearing and longer service life. Low-iron tempered solar glass as cover with 92% transmittance. Our flat panel solar collector approved by SOLAR KEYMARK(EN12975 Standard)High Quality Parts:

Incoloy 800 Electric Element

Incoloy 800 Electric ElementCE Approved

P/T Safety Valve

P/T Safety ValveWater Mark Approved

Intelligent Controller

Intelligent ControllerCE Approved

Magnesium Anode

Magnesium AnodeTechnical Parameters:

Jacketed Water Tank:

| Tank Capacity | 100L | 150L | 200L | 250L | 300L |

| Outer Tank Diameter(mm) | Φ540 | Φ540 | Φ540 | Φ540 | Φ540 |

| Inner Tank Diameter(mm) | Φ440 | Φ440 | Φ440 | Φ440 | Φ440 |

| Inner Tank Material | Steel BTC340R(2.5mm thick) | ||||

| Heat Exchanger | Jacketed Shell(1.8mm thick) | ||||

| Inner Tank Coating | Porcelain Enamel(0.5mm thick) | ||||

| Outer Tank Material | Color Steel(0.5mm thick) | ||||

| Insulating material | Rigid polyurethane foam | ||||

| Insulation thickness | 50mm | ||||

| operating Pressure | 6bar | ||||

| Corrosion protection | magnesium anode | ||||

| Electric Element | Incoloy 800(2.5kw,220v) | ||||

| Adjustable Thermostat | 30℃~75℃ | ||||

| TP Valve | 7bar,99℃(water mark approved) | ||||

Flat Panel Solar Collector:

| Dimension | 2000*1000*80mm | |

| Gross area | 2m2 | |

| Aperture area | 1.85m2 | |

| Absorber | Aluminum Plate | |

| Selective Coating | Material | Germany Blue Titanium |

| Absorptivity | ≥95% | |

| Emissivity | ≤5% | |

| Header Pipes | Copper (¢ 22*0.8mm)/(¢ 25*0.8mm) | |

| Riser Pipes | Copper (¢ 8*0.6mm)/(¢ 10*0.6mm) | |

| Cover Plate | Material | Low - iron tempered glass |

| Transmittance | ≥92% | |

| Frame | Aluminum alloy | |

| Base plate | Galvanized plate | |

| Base Insulation | Glass wool | |

| Side Insulation | polyurethane | |

| Sealing material | EPDM | |

| Max test pressure | 1.4MP | |

| Max work pressure | 0.7MP | |

How It Works:

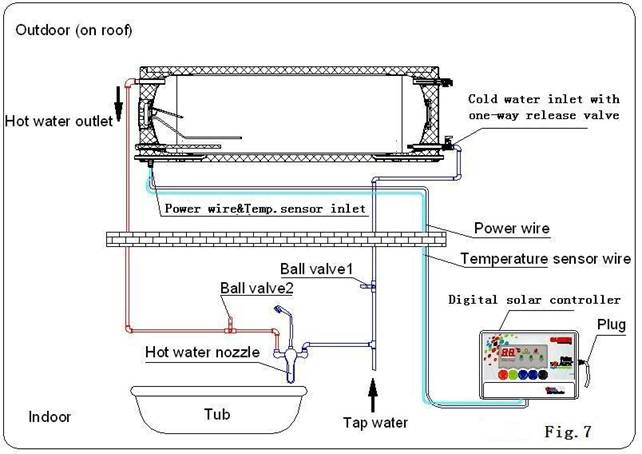

The system operates on the thermosiphon principle, meaning that heat transfer occurs entirely by means of natural convection, without pumps and control units. The solar fluid heated in the collector rises and transfers heat through a highly efficient jacketed shell. High-selectivity harp absorbers are used to guarantee the highest possible solar yield in this system.

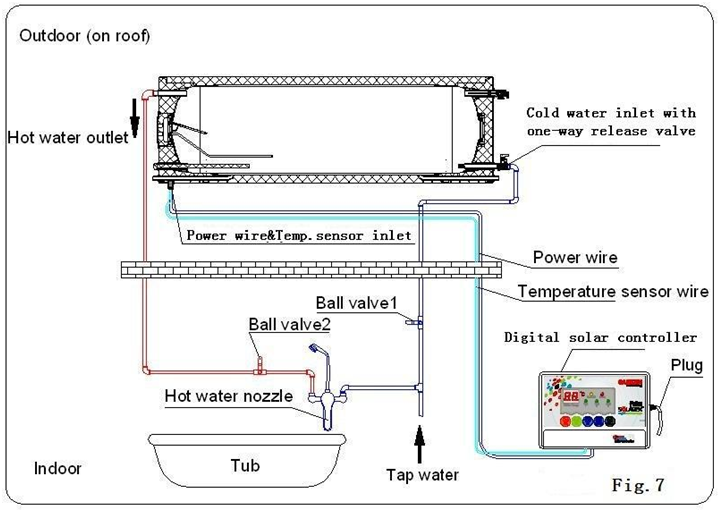

System Installation Diagram

Installation and Operation Manual:

- Thank you for selecting our closed loop flat panel solar water heater with so many advantages. Elegant shape, high efficiency, working under pressure, easy to use、safe and reliable. it’s your best solution to supply hot water for family. Please read carefully the manual before use.

- Please check accessories and user’s manual according to the packing list when opening the package.

- Local agent or franchised store take charge of the installation& trail run and after service, please write down the telephone number and address of the store where you purchase from in order to get our timely service.

- Both package and warranty card have serial number. Neither no series number nor damaged series number may be fake. please pay more attention to it.

- Make sure to mix hot and cold water before shower or washing. Otherwise.it will cause severe burn.

- Warning: Please fill up with cold water before heated by electrical back up element

- Use hot water while the electrical back up element is working is strictly forbidden.

- The connection of wire is “X” way. You must use sheathed copper wire with three cords(size:≥1.5mm2)when you install or replace the wire.

- Please keep the cold water valve open at all times.

1) Advanced Technology

Closed loop flat panel solar water heater with separate water tank and flat panel can get hot water according to thermosiphon principle. Enamel coated inner tank is made of special metal material. formed up with advanced punching technology and atuo non-electrode replacing welding technology. a special silicate is sintered by high temperature to the wall of inner tank.forming a special protection layer with no leakage, no corrosion, no scale advantages .

2) Flat panel

The most efficient Germany imported blue titanium selective coating.

Minimize the damage to absorption layer and copper pipe with whole plate laser welding.

High strength special low-iron tempered glass with transmittance more than 92%.

High quality assured with advanced producing process technology and equipment.

3) Double Protecting

Imported P/T valve provides the automatic pressure release and protects the water tank against the influence of high temperature and pressure. One-way water-in release valve can drain out water automatically and resist the influence of super-high water pressure outside.

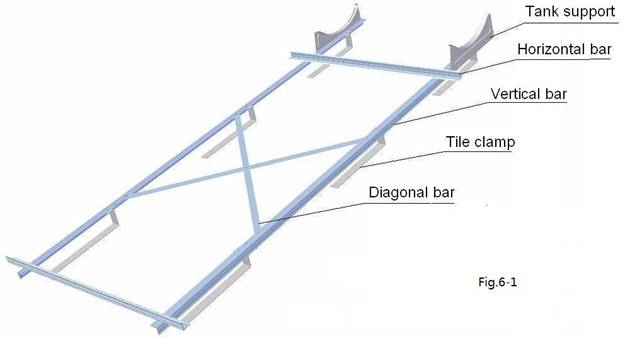

4) Aluminium Alloy Bracket

It’s made of Al-Mg-Si antirust aluminium alloy material and produced by advanced numerical control(NC) equipment with high hardness and strength.

5) Wide Scope Of Application

The jacket type structure with medium which will not freeze under -35℃ has high heat exchange efficiency and high systematic stability. it can be installed and used in the tropic, temperate zone and frigid zone.

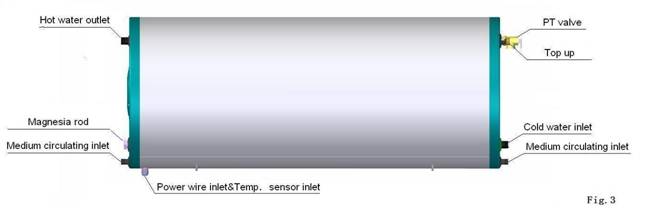

2. Water Tank

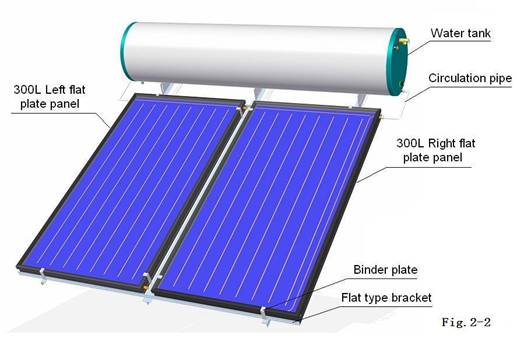

3.1 Single Flat Panel For Small Capacity Water Tank

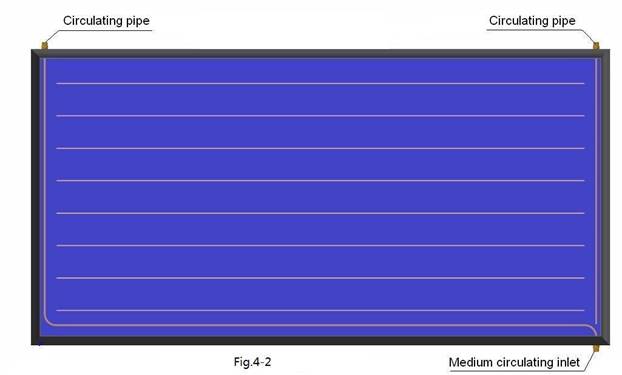

3.2 Right Flat Panel For Big Capacity Water Tank

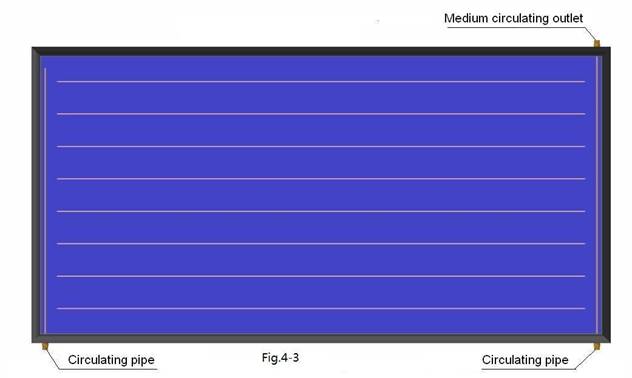

3.3 Left Flat Panel For Big Capacity Water Tank

1) The six tile clamps must be fixed firmly on the sloping roof first.

2) Assemble right&left tank supports,right&left vertical bars, and six tile clamps with M6x16 screws&nuts.

3) Assemble two horizontal bars and right&left vertical bars with M8x20 screws&nuts.

4) Assemble one set of diagonal bars and right & left vertical bars with M6x16 screws & nuts.

1.2 Installation of sloping type aluminium alloy bracket for big capacity water tank

1) The nine tile clamps must be fixed firmly on the sloping roof first.

2) Assemble right&middle&left tank supports,right&middle&left vertical bars, and nine tile clamps with M6x16 screws&nuts.

3) Assemble two horizontal bars and right&left vertical bars with M8x20 screws&nuts.

4) Assemble two sets of diagonal bars and right&middle&left vertical bars with M6x16 screws&nuts.

2. Installation of water tank

Set the water tank symmetrically on the supporting bracket and fix with M8 nuts.

3. Installation of flat panel

Set the flat panel symmetrically on the supporting bracket and fixed by binder plate with M6x12 screws&nuts.

4. Connection of flat panel and water tank

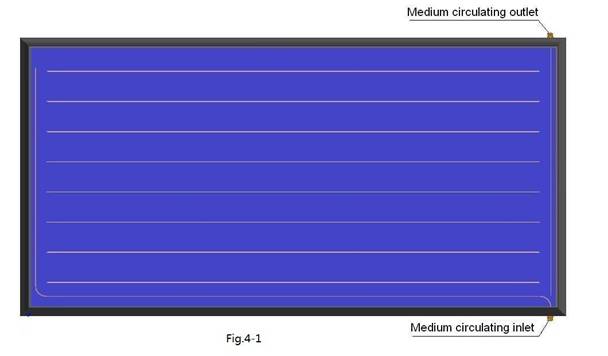

Connect the medium circulating outlet of flat panel to the medium circulating inlet of water tank with SUS304 corrugated pipe and Connect the medium circulating inlet of flat panel to the medium circulating outlet of water tank with SUS304 corrugated pipe.

5. Fill the circulating medium

Unscrew the “top up”cover at the right side of water tank and then fill the circulating medium according to III.technical parameters in case of excess circulating medium damages water tank because of high pressure.

6. Connection of inside water pipes and outside water pipes

7. Installation of intelligent controller:

Caution

● The socket and plug should be connected well.

● If auxiliary electric heating system installed, do connect the live wire, null wire and ground wire correctly with power-leakage protection plug. The socket should be connected to ground reliably.

● Use tri-wire plug of safe protection, and the rated current value of socket ≥16A

● Safe measures should be taken and layout to specification.

● Installation of digital solar controller

● The light collecting plates should face south with nothing blocked, and supports be reliable to anti-strong wind.

● Filling water: The heater is filled water by pressure and free of filling device, water will be automatically filled till fullness and then stops.

● Using water: Water can be used under pressure.