Product Description:

Heat pump water heater works on principle just like an air conditioner or like the refrigerator. It absorbs warmth from the air and transfer it to heat water. Hence it’s also referred to as air-source heat pumps. It operates on electricity but is more efficient than a conventional electric water heater.

GOMON high-efficiency all in one heat pump water heaters provide an energy efficient and innovative water heating solution for your house.

Enamel Water Tank Brings You Healthier Water Quality

High pressure and fatigue resistance which pass 280,000 times pulse test.

High corrosion resistance because enamel coating makes the welding line of steel plate seperate with water, so with long working life.

Our Porcelain enamel tanks approved by CE, WATER MARK, ETL, WRAS, EN12977-3.

High efficient Micro-Channel Heat Exchanger

Larger heat exchange area, Better heat transfer effect and More durable performance.

The Coefficient of Performance of the system can reach 4.25 even above.

Not touch with water in the water tank, so the heat exchanger has no risk of corrosion, scaling, leakage, etc.

Library Level 40dB Silence

Centrifugal fan, smooth air intake

Double plate air guiding, optimizing air duct

Double layer soundproofing, reducing radiation

Double piece evaporator makes it more optimized

High Efficient Compressor

Being internationally-renowned brand dedicated compressor for heat pump, it is more reliable in system matching and quieter in operation.

Intelligent Defrosting

With intelligent defrosting design, it can revolutionarily solve the bottlenecks of heat exchangers in cold winter such as frosting and slow heating, etc., allowing you to spend a more comfortable winter.

1:1 Gold Ratio

The unit and water tank are matched with a gold ratio to eliminate the phenomenon of disharmony, so that it is more energy-saving and professional.

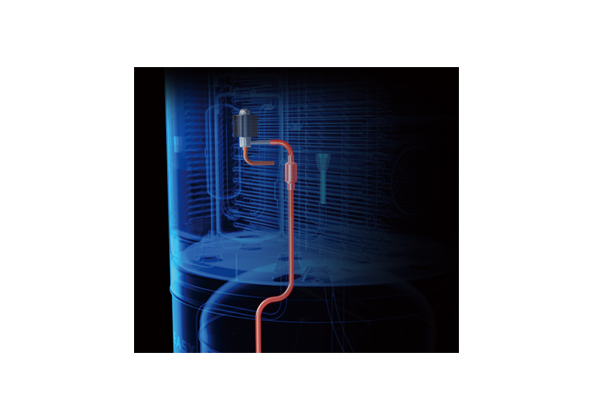

Intelligent Control Electric Expansion Valve

The electric expansion valve can control the refrigerant volume more accurately to ensure the unit stay in the best state.

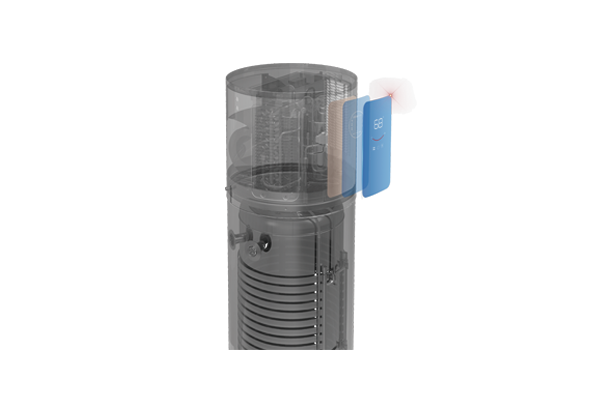

Smart and Convenient Touch Control

Intelligent light display

WIFI control

Real Images and Details:

Technical Parameters:

| Model | KRS38A-160V | KRS38A-200V |

| Tank Capacity | 160L | 200L |

| Inner Tank Material | Enamelled Steel (Steel BTC340R, 2.5mm thickness) | Enamelled Steel (Steel BTC340R, 2.5mm thickness) |

| Outer casing | Painted galvanized steel | Painted galvanized steel |

| Tank Rated Working Pressure | 0.8MPa | 0.8MPa |

| Waterproof grade | IPX4 | IPX4 |

| Condenser | Micro-Channel Heat Exchanger | Micro-Channel Heat Exchanger |

| Electric Element Power | 2500W | 2500W |

| Heat Pump Rated Input | 420W | 420W |

| Heat Pump Output | 1780W | 1780W |

| Max. Input Power | 3200W | 3200W |

| Heating Capacity | 38L/H | 38L/H |

| Max. Water Temperature | 75℃ | 75℃ |

| Voltage | ~220-240V / 50Hz | ~220-240V / 50Hz |

| Refrigerant | R134a | R134a |

| Energy efficiency Grade | Grade A | Grade A |

| Inlet / Outlet size | ¾” | ¾” |

| Control Method | Touch screen | Touch screen |

| Noise Level | 40dB(A) | 40dB(A) |

| Dimensions | Ø525×1735 | Ø525×1955 |

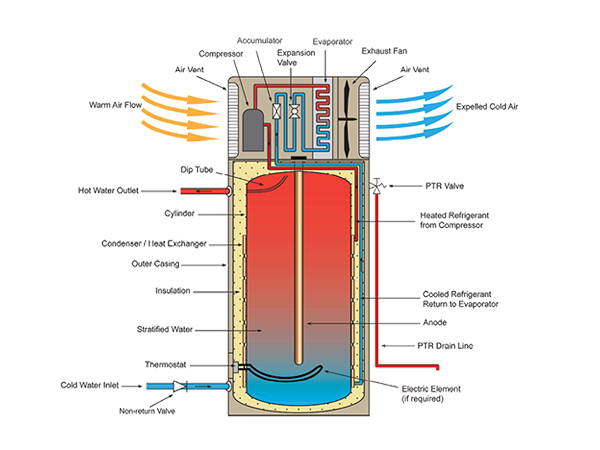

How It Works:

All in one heat pump water heaters are solutions where the domestic hot water is heated by an integrated heat pump

- The fan inhales ambient air transferring its energy to the refrigerant agent in the evaporator thus changing from liquid to gas.

- The gas is further heated by compression.

- In the condenser the gas transfers its accumulated heat to the water tank. As it gets colder it transforms back to fluid. The pressure of the fluid is further reduced by the expansion valve.

- The electric back-up heating starts only when required during insufficient heat pump working conditions.

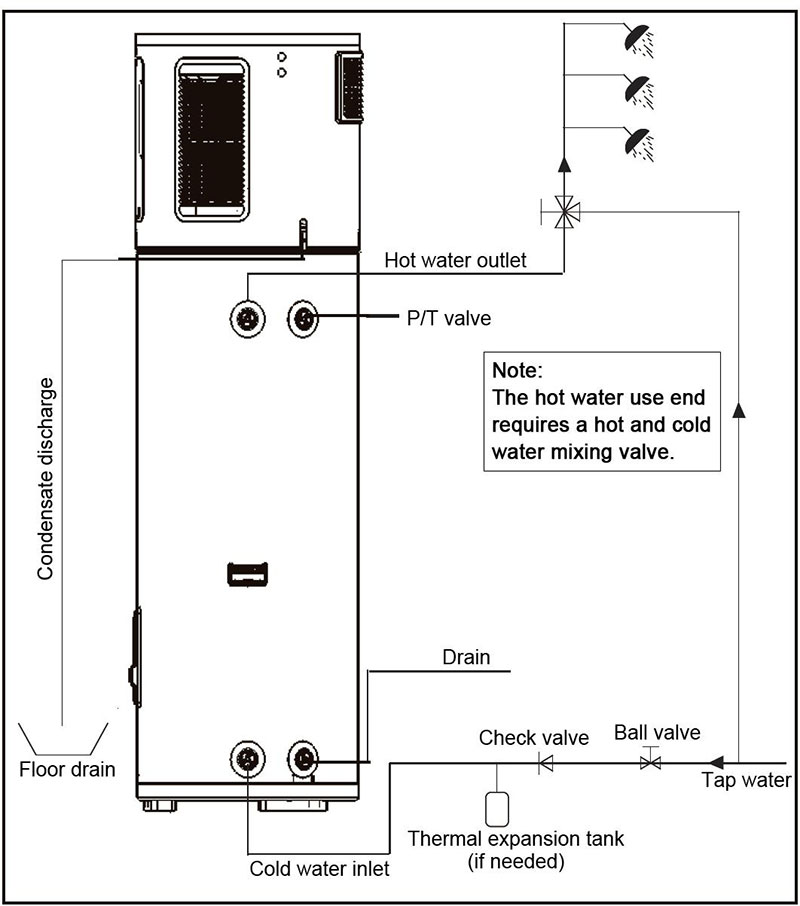

System Installation Diagram

Installation and Operation Manual:

The equipment should be placed where it won’t damage the adjacent area or underlying structure of the heat pump water heater even if there is leak at the water heater or the joint. When these installation locations cannot be avoided, it is recommended to install a suitable water drain pan in the lower part of the water heater for adequate drainage of water.

If the water heater is installed in a closed water supply system, measures should be taken to prevent hot water from flowing back; for example, a check valve is installed on the cold water supply pipeline to prevent hot water from flowing back due to thermal expansion.

Before manually operating the temperature and pressure safety valve (hereinafter referred to as P/T valve), preventive measures must be taken to avoid the risk of scalds by the hot water flowing out from the P/T valve.

The thermal expansion of the closed water supply system may cause the P/T valve to periodically relieve pressure. Contact the water heater supplier for how to correct this situation. DO NOT BLOCK THE P/T VALVE.

The P/T valve should be inspected every 6 months for its performance or replaced at an interval of not more than 2 years. The P/T valve should be replaced more frequently in the high-occurrence areas of water subsidence.

When using and reusing the refrigerant, please comply with relevant environmental regulations. The refrigerant is not allowed to be discharged into the environment. R134a refrigerant is used for this equipment, which is non-flammable and does not have a devastating effect on the ozone layer.

When processing or operating components related to the refrigerant circuit, the refrigerant should be discharged to ensure safe operation.

The high pressure insulation test of the equipment can only be carried out between the live wire and the ground wire as well as the null line and the ground wire. The test between the live wire and the null line will damage the electronic equipment.

All electrical installation and wiring must be performed by qualified professionals and subject to wiring rules and the requirements of the local authority.

Risk of electric shock: Please turn off the power before performing equipment repairs. Failure to do so may result in serious personal injury or death.

When the circuit board, controller or display is repaired, all wires shall be first labeled and then disconnected. Wiring errors can result in incorrect and dangerous operation. The wiring must be reconfirmed after repair.

The water tank may be frost-cracked due to low temperatures. Do not turn off the power to the equipment. If it needs to turn off the power or there is a power outage, and there may be frost- crack because of low temperatures, the water should be discharged from the water tank.

Do not store or use gasoline or other flammable, explosive or corrosive gases and liquids near this equipment.

The water heaters must be installed, commissioned and repaired by authorized personnel in accordance with local laws and regulations.

It should ensure that the surrounding area of installed equipment is clean and free of flammable and corrosive materials such as gasoline and other flammable, explosive and corrosive gases and liquids, etc.

The power supply of the water heater can only be turned on after the water tank has been filled with water.

Water temperatures above 50 °C can immediately lead to severe burn or scald and death. Please feel the water temperature before bathing or showering.

Prevent the risk of scald by high-temperature water:

In order to prevent scalds caused by excessively high water temperature, we recommend installing a temperature limiter at the junction of the hot water pipe and the sanitary water outlet (i.e the toilet and bathroom). This will keep the water temperature at the outlet below 50 °C, which can reduce the risk of scalds.

Water temperatures above 50 °C can cause severe scalds, and the local regulations and requirements regarding temperature limits primarily for personal sanitary hot water must be considered.

The water heaters must be installed by authorized personnel and the installation must comply with the local laws and regulations and the requirements of the supervision organization.

Faulty operation can result in death or serious injury.

This manual has clearly stated the possible risks. We will not be liable for any consequences resulting from failure to apply the equipment in accordance with the requirements of this manual.

♦ Easy to operate

The equipment adopts the user-friendly control panel, which is easy for users to operate.

♦ Energy saving and environmental protection

The equipment heats water by absorbing energy from the surrounding air and releasing it into the water stored in the tank, so it is very energy efficient. If the ambient temperature is low, the heating capacity of the heat pump will decrease, and then the auxiliary electric heater can be used as a backup.

♦ Overheating protection

The water tank is equipped with a thermostat protection device located above the electric heater and it is in contact with the inner tank surface. If the water temperature reaches preset temperature or there is no water in the tank due to any cause, the thermostat will automatically cut off the power circuit of the electric heater.

When the water temperature is higher than 95 °C, the manual protection device of thermostat will cut off the power supply. If the temperature returns to the normal level later, the thermostat needs to be turned on by manual reset.

♦ Automatic defrosting

In the operating state of heat pump, the equipment will automatically defrost to ensure thermal efficiency.

♦ Water temperature or pressure protection

For your safety, the equipment is equipped with a P/T valve. If the tank pressure reaches 800 kPa or the temperature reaches 90°C, the valve will automatically open to allow the pressure or temperature to drop to a safe value.

♦ Water supply pressure

The water heater is designed to be directly connected to the water system. When the water supply pressure exceeds 800 kPa, a pressure limiting valve must be installed. The minimum water supply pressure of 200 kPa is required to ensure the normal water supply of the water heater.

If the P/T valve or other safety devices has been tampered or not been installed in accordance with the instructions in this manual, the company will not be responsible for the consequences.

2.2 Working mode

♦ AUTO mode:

Water temperature setting: 35~75°C;

The heat pump can be heated up to 65oC at maximum, and it will shut down when the water temperature is heated to 65oC.

♦ Eco mode (Energy saving mode)

It is a timing mode.

The heat pump will automatically start and shut down when the startup & shutdown time is pre-set. It can be heated up to 65°C at maximum, and it will shut down when the water temperature is heated to 65°C.

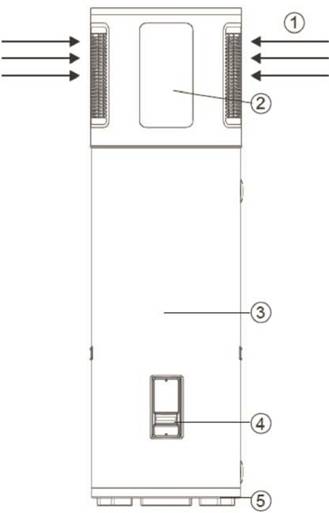

2.3 Product appearance

[1] Air inlet

[2] Control panel

[3] Water tank

[4] Electric heater & Thermostat

[5] Foot

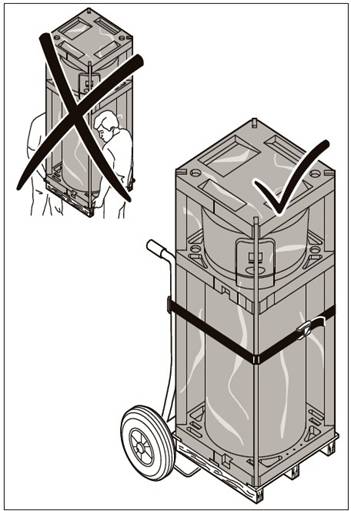

As a rule, the equipment should be packed erectly and the water tank be stored or transported as an empty water tank. For short-distance transport, care should be taken to allow a tilt angle of 30° at maximum. Whether transported or stored, the ambient temperature should be in the range of -20 °C~

+60°C.

3.2 Handling

When handled and transported by a forklift, the equipment must be fixed to the pallet at all times. The

lifting rate should be kept at the lowest limit. Due to the top-heavy weight, anti-overturn measures must be taken. To prevent any damage, the equipment must be placed on a level surface!

For manual handling, it is necessary to ensure that the lifting belt and pallet are used for the bottom.

It must be noted that the maximum allowable tilt angle cannot exceed 30°. If tilting cannot be avoided during handling and transportation, the equipment can only be operated one hour after being moved to the final vertical position.

The use of unauthorized devices may shorten the life of the water heater and may result in death and property damage. The manufacturer is not responsible for any loss or damage caused by the use of such unauthorized devices.

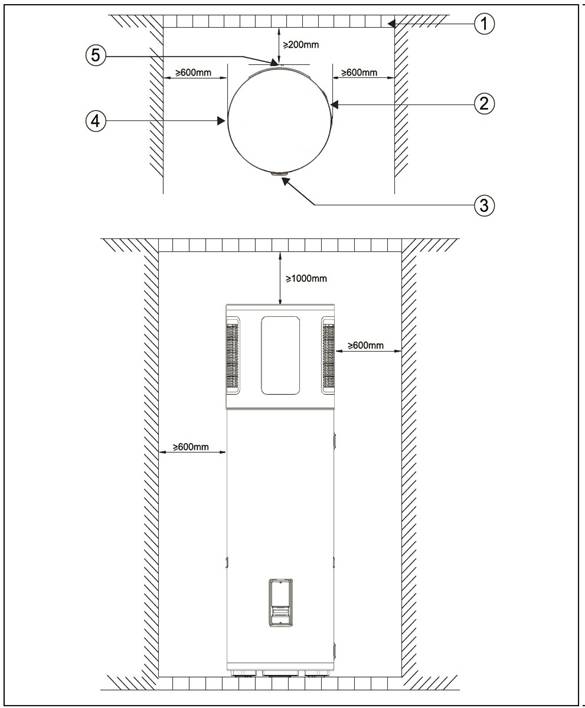

4.1 Placement space requirements

Installation space requirements: to avoid affecting airflow, please ensure the equipment space requirements as shown.

[1] Wall [2] Condensate drain outlet [3] Control panel [4] Air inlet [5] Air outlet

If any insulation material or covering is applied on the outside of the water heater, the following points need to be noted:

♦ Do not cover the P/T valve.

♦ Do not cover the lid of the auxiliary electric heater.

♦ Do not cover the operation, warnings and other marks on the water heater.

♦ Do not cover the air inlet and outlet.

♦ Do not cover the control unit of water heater.

Before manually operating the P/T valve, make sure that no one will be exposed to danger because of contacting the hot water released by the valve. The water may not heat up to the level of scald, however it is still necessary to use a suitable drain pipe to release the water to avoid possible injury or property damage.

Periodic release of the P/T valve is part of normal operation. This is because there is thermal expansion in a closed water system that causes an increase in pressure. If such release becomes excessively frequent and continuous, please contact the after-sales service provider and don’t block the outlet of the valve.

Note: Proper maintenance of the water heater will provide a longer, reliable, trouble-free and economical operating life.

It is recommended to establish a regular preventive maintenance program for the users to follow up.

6.1 Inspection and maintenance precautions

It is recommended that periodic inspections of the controller, heating elements, and wiring should be performed by qualified electrical service personnel.

It is recommended that the evaporator and refrigeration circuit be inspected and cleaned every 5 years for dust and residue. In dusty environments, they should be inspected and cleaned more frequently.

| Abnormal conditions | Warning code | Action | Recovery mode |

| Low-voltage warning | A12 | Stop heating | Automatic recovery or Manual recovery, settable (F51, F52) |

| Upper water temperature probe failure | A20 | Stop heating | Automatic recovery or Manual recovery, settable (F54, F55) |

| Lower water temperature probe failure | A21 | Stop heating | Automatic recovery |

| Coil probe failure | A22 | - | Automatic recovery |

| Exhaust probe failure | A23 | - | Automatic recovery |

| Environmental probe failure | A25 | - | Automatic recovery |

| Suction probe failure | A26 | - | Automatic recovery |

| Interrupted connection with the external board | A51 | Stop heating | Automatic recovery |

| Excessively high exhaust temperature | A61 | Stop heating | Automatic recovery after reduction of exhaust temperature within three times |

Package

We participate in the recycling programs of various countries to ensure optimal recycling. All our packaging materials are environmentally friendly and recyclable.

Old Equipment

The old equipment containing valuable materials should be recycled. These components can be easily separated and composited and also marked accordingly. Therefore, these components can be classified and further recycled or disposed of.

Prior to the end of the service life of this equipment, the personnel who have operational qualifications to the refrigeration circuit must recycle the refrigerant from the sealing system based on the preferred consideration of environmental protection.