Product Description:

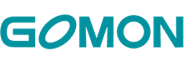

This is a pressurized system, with direct tank and flat panel solar collector combined.We call it compact flat panel pressurized solar water heater.

Open-loop systems are simply and fast way of water heating. They are best suited to warm climate regions because of operating directly with potable water. Open-loop systems are not recommended in regions where water quality is not good enough.

Product Features:

The enamel is coated inside the water tank which is of high corrosion resistance and of great pressure bearing. Our porcelain enamel tanks approved by CE, WATER MARK, ETL, WRAS, EN12977-3

The whole system approved by SOLAR KEYMARK (EN 12976 Standard)

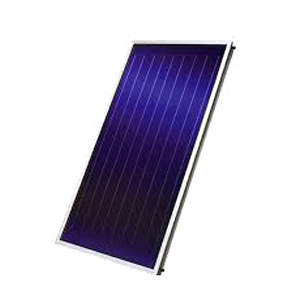

The whole system approved by SOLAR KEYMARK (EN 12976 Standard) Imported blue titanium absorber from Germany with high absorptivity(95%) and low heat loss(5%). High purity oxygen-free copper pipes as circulation system with high thermal conductivity, anti-corrosion pressure-bearing and longer service life. Low-iron tempered solar glass as cover with 92% transmittance. Our flat panel solar collector approved by SOLAR KEYMARK(EN12975 Standard)

Imported blue titanium absorber from Germany with high absorptivity(95%) and low heat loss(5%). High purity oxygen-free copper pipes as circulation system with high thermal conductivity, anti-corrosion pressure-bearing and longer service life. Low-iron tempered solar glass as cover with 92% transmittance. Our flat panel solar collector approved by SOLAR KEYMARK(EN12975 Standard)High Quality Parts:

Incoloy 800 Electric Element

Incoloy 800 Electric ElementCE Approved

P/T Safety Valve

P/T Safety ValveWater Mark Approved

Intelligent Controller

Intelligent ControllerCE Approved

Magnesium Anode

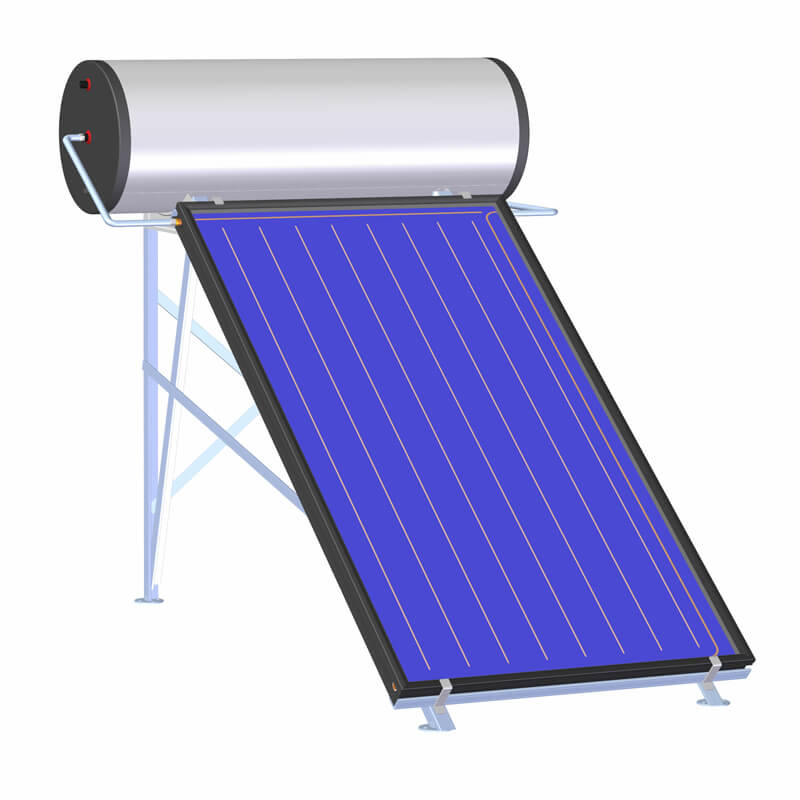

Magnesium AnodeReal Images and Details:

Technical Parameters:

Direct Water Tank:

| Tank Capacity | 100L | 150L | 200L | 250L | 300L |

| Outer Tank Diameter(mm) | Φ540 | Φ540 | Φ540 | Φ540 | Φ540 |

| Inner Tank Diameter(mm) | Φ440 | Φ440 | Φ440 | Φ440 | Φ440 |

| Inner Tank Material | Steel BTC340R(2.5mm thick) | ||||

| Inner Tank Coating | Porcelain Enamel(0.5mm thick) | ||||

| Outer Tank Material | Color Steel(0.5mm thick) | ||||

| Insulating material | Rigid polyurethane foam | ||||

| Insulation thickness | 50mm | ||||

| operating Pressure | 6bar | ||||

| Corrosion protection | magnesium anode | ||||

| Electric Element | Incoloy 800(2.5kw,220v) | ||||

| Adjustable Thermostat | 30℃~75℃ | ||||

| TP Valve | 7bar,99℃(water mark approved) | ||||

Flat Panel Solar Collector:

| Dimension | 2000*1000*80mm | |

| Gross area | 2m2 | |

| Aperture area | 1.85m2 | |

| Absorber | Aluminum Plate | |

| Selective Coating | Material | Germany Blue Titanium |

| Absorptivity | ≥95% | |

| Emissivity | ≤5% | |

| Header Pipes | Copper (¢ 22*0.8mm)/(¢ 25*0.8mm) | |

| Riser Pipes | Copper (¢ 8*0.6mm)/(¢ 10*0.6mm) | |

| Cover Plate | Material | Low - iron tempered glass |

| Transmittance | ≥92% | |

| Frame | Aluminum alloy | |

| Base plate | Galvanized plate | |

| Base Insulation | Glass wool | |

| Side Insulation | polyurethane | |

| Sealing material | EPDM | |

| Max test pressure | 1.4MP | |

| Max work pressure | 0.7MP | |

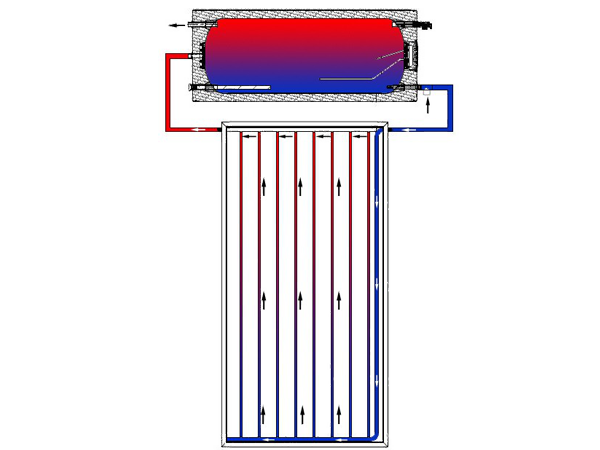

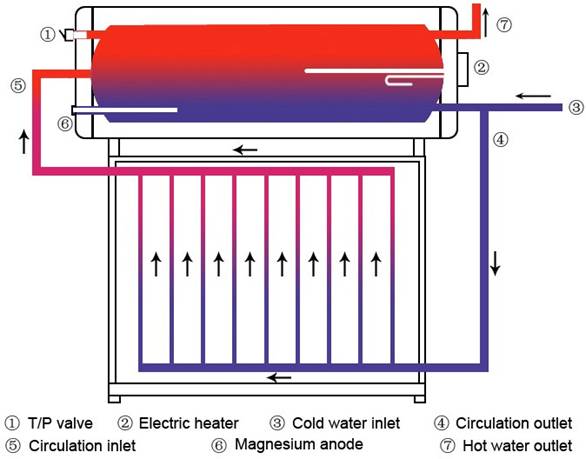

How It Works:

The system operates on the thermosiphon principle, It adopts the water-water circulation type. Heat adsorption membrane on the flat plate absorbs the solar heat to heat the water in the heat collector directly. Deliver the heated water to the upper part of hot water storage tank via circulation pipe and unheated cold water in the lower part flows into the flat-type heat collector as supplementation. Then cold water is heated and delivered to the hot water storage tank. The circulation of water repeats till all water in the water tank is heated to the specified temperature.

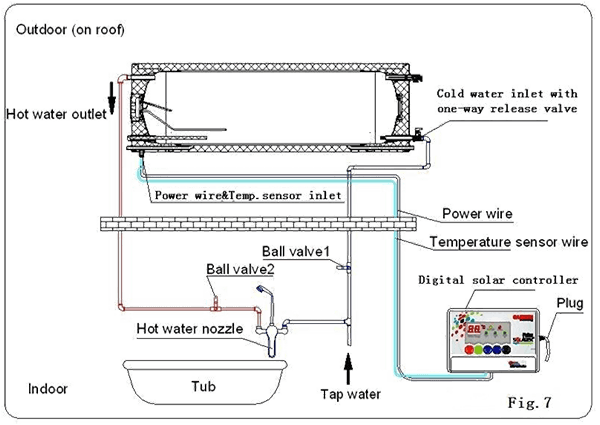

System Installation Diagram

Installation and Operation Manual:

1.1 Advanced technology

The core parts of the solar water heater – flat plate solar collector and enameled steel inner tank involve numerous national patented technologies. The solar collector with advanced technology in gathering solar energy features water-tightness, high heat absorption, independent heat supply, fast energy output, wide scope of application and long working life.

1.2 Low heat loss

With imported polyurethane foam en-bloc high pressurized, which is of high density and strength, the solar water heater has excellent heat insulation.

1.3 Superb process technology

The inner tank is made of special steel, formed up with advanced punching technology and auto non-electrode replacing welding technology. A special silicate is sintered by high temperature to the inner tank’s walls, forming a special protection layer featuring freedom of leakage, rust/erosion and scaling, thereby effectively preventing leakage between the water tank and the heat-gathering tubing and ensuring the cleanness of water.

1.4 Easy for functional extension

This solar water heater can be equipped with a computerized controller and electric heater. The user has a few options depending on his actual needs.

2.1 Flat plate panel

2.2 Water tank

2.3 Bracket (sloping roof & flat roof)

2.3.1 Sloping roof bracket

2.3.2 Flat roof bracket

3.1 Installation of solar panel

The flat panel(s) is fixed with the “Z” fasteners:

3.2 Installation of Water Tank and Bracket

Firstly fix the hunger on the tank.

Then set water tank symmetrically on the bracket and fixed with the M9 nuts.

3.3 Connection between solar panel and water tank

Please pay attention to the following drawing and picture when installing pipelines.

If solar water heater is equipped with two or three units of solar collectors, please see the connection of two solar collectors from the marks C and D.

3.4 Installing computerized controller

If the solar water heater is equipped with one computerized controller, please carefully read the Controller’s User Manual before installing and operating the Controller.

The Controller should be located in a prominent location that is accessible to the homeowner. Care should be taken to ensure that the controller is not placed where it is within easy reach of children, near electromagnetic fields or in damp locations.

Attention!

▲ The socket and plug should be connected well.

▲ If electric heater is installed, do connect the live wire, null wire and ground wire correctly with power-leakage protection plug. The socket should be connected to ground reliably.

▲ Use tri-wire plug of safe protection, and the rated current value of socket ≥10A.

▲ Wiring according to controller instruction manual.

4.1 Prohibition of isolation without water

Under normal circumstances, keep the water tank full. If the solar water heater is not used for a long time, the heat collecting tubes should be covered with shade cloth.

4.2 No shadow

The solar collectors face south without shelter.

4.3 Wind stress

When installing solar water heater, please consider the issue of wind resistance, and resultant stress on attachment points.

4.4 P/T valve

4.4.1 Please refer to separate P/T valve instruction manual for operating.

4.4.2 Following installation, the P/T valve lever MUST be operated AT LEAST ONCE A YEAR by the solar water heater owner to ensure that waterways are clear.

4.4.3 The P/T valve should be inspected AT LEASE ONCE EVERY TWO YEARS, and replaced, if necessary.

4.5 Magnesium anode

The magnesium anode should be inspected at the timely basis to extend the life of water tank according to water quality.

Replace the magnesium anode AT LEAST ONCE TWO YEARS.

4.6 Water Quality

In areas with “hard” water, lime scale may foam inside the safety valve and P/T valve. In such regions, it is advisable to install a water softening device.

4.7 Expansion tank

In areas with high temperature weather, the pressure inside water tank rises quickly. It is an optional means to install a suitably sized expansion tank significantly minimize the amount of hot water dumped by the P/V valve due to overpressure.